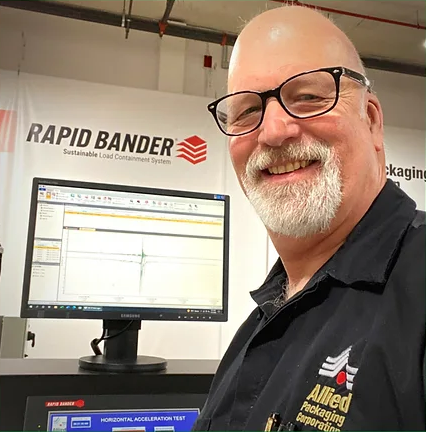

Ask Steve

July 26, 2023

Question from Ray: I see that your Rapid Bander system uses 2 rolls of film as opposed to the normal 1 roll. Does it mean that each revolution of the machine counts for 2 wraps?

Hi Ray, thanks for the question and the opportunity to clarify something that a lot of people have misunderstood.

The quick answer: we apply one wrap for each revolution of load, not two. Or to put it another way, you are wrapping the pallet with a single web of film, formed from two layers provided by the two rolls. Now, let me explain why, even with two rolls, you are not applying more film to your pallet.

First, each roll of Rapid film is significantly thinner than the single roll of the stretch film you are using now.

Second, we stretch the film much more, without breaking the web, than you can using conventional film, which means you can wrap far more pallets with the same amount of dispensed film.

The net result is that even with two rolls of film, you are using up to 50% less film per pallet.

Now for my favorite part, why we use two rolls of film (or the science behind the Rapid Bander)!

One of the two rolls is a full web, (20” or 30” in width depending on your machine’s carriage). The second roll is split into bands, three for a 20” roll and four for a 30” roll. Each band is passed through a set of adjustable rollers which narrow the band by rolling its edges. The rolled edges of the bands become reinforcement filaments, six for a 20” roll and 8 for a 30” roll. The bands are then incorporated into the full web, and as they pass through the pre-stretch carriage, they laminate to form a single reinforced web as it exits the carriage.

Here’s why these filaments are so important and how they provide exceptional load containment. You can also demonstrate for yourself how they reinforce the web the next time you are in the plant. Find the bin where the operators place used rolls they remove from the machine. There is normally a little film left on the core. Remove a length of film from the core being careful not to crumple it. Now grasp each end and pull as far as you can. Note the force required to stretch it. Now, cut another piece of film about the same length. This time, roll the film up so it looks like a rope. Grasp each end and pull as far as you can. You will find the effort needed to stretch the second film sample is MUCH higher than the first piece you stretched. When you have multiple filaments embedded in the full web, the force required to stretch the film is significantly higher than a single roll of conventional film.

But what does that have to do with load containment? During transportation, forces are constantly applied to the load. The primary job of the stretch wrap is to counter those forces with an equal and opposite force. If the applied force exceeds the stretch film’s resistance to it, the film stretches and the load moves. The more the load moves, the closer you are to load failure. Let me give you an illustration. Picture a piece of plywood that represents the side of the load. The plywood has handles on both sides. Imagine two people one on each side of the plywood, pushing as hard as they can. One side represents the applied force during transportation and the other the stretch film’s resistance to stretch. If the stronger individual is representing the applied force, then the plywood will move, just like your load.

From your hands-on experience, you can visualize how the filaments used in the Rapid Bander system can provide more resistance to stretch (up to nine times as much) than conventional film during transportation. It’s all about the science of load containment.

We look forward to helping you achieve improved load containment, reduced film usage, improved equipment throughput by reduced wrap count, all the while lowering your annual film spend.

Thanks for asking!